NETWORKANALYSIS

Safety – Stability- Reliability

FUNCTIONAL DESCRIPTION

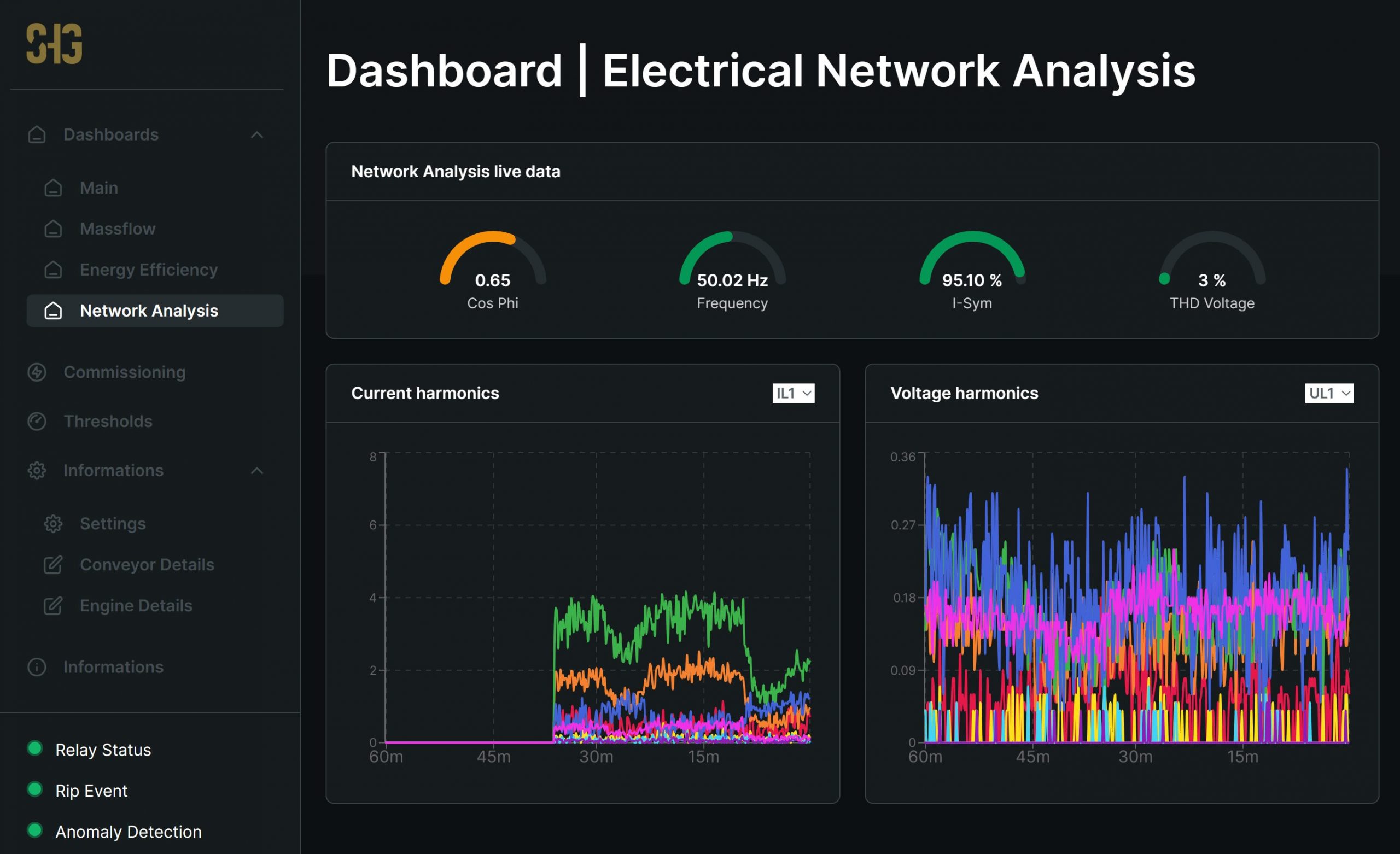

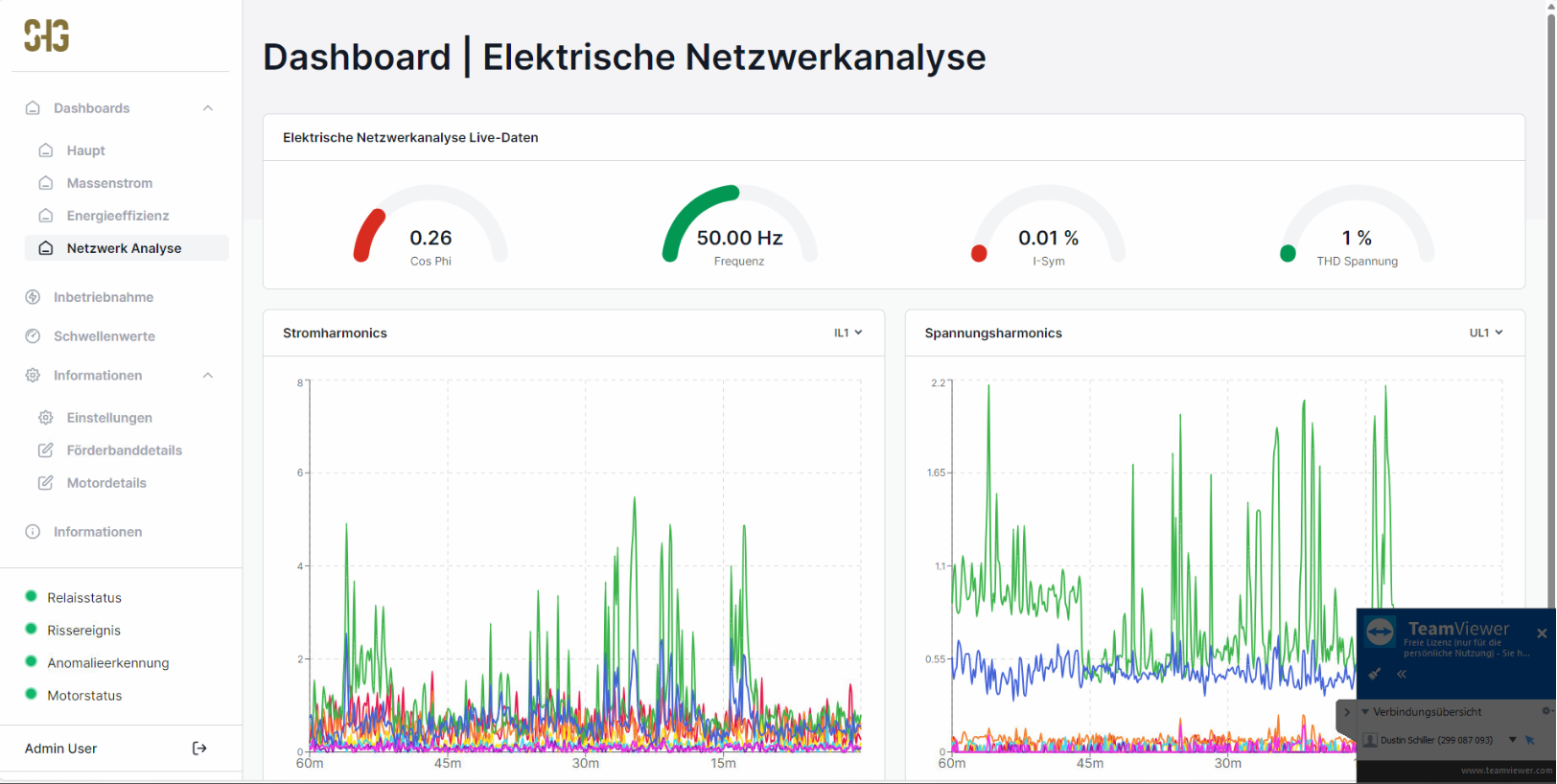

ELECTRICAL NETWORK ANALYSIS

The electrical grid analysis is realised by installing the Rip Prevent+ system at various points in the company. Electrical and electronic systems often influence the power quality. However, they themselves react very sensitively to any disturbance. Such problems with the power quality can lead to malfunctions or unexpected shutdowns of protective devices and thus to the shutdown of processes and systems. Flickering lighting or more frequent and “hidden”, incomprehensible system crashes are also often indicators of inadequate network quality. One of the most drastic consequences is an increased risk of fire in electrical and electronic components The Rip Prevent+ system helps you to optimise the power quality and reduce the load on the electronic components.

INPUT PARAMETERS

- Motor informations

- Network information

- Process information

- Electrical Parameters

- Massflow

- Temperatur

- …

BENEFITS

- Live view of the electrical grid

- Utilising the functions of the Rip Prevent+ system

- Increased safety

- Reduction of unplanned downtime

- Included in license

- …

RIP PREVENT+ FUNCTION

RIP DETECTION

RIP PREVENTION

ANOMALY DETECTION

MASSFLOW CALCULATION

ELECTRICAL NETWORK ANALYSIS

ENERGYEFFICIENCY

DRIVE MONITORING

FUTURE ADD ONS

IMPRESSIONS

This is how you can reach us!

Am Teichhof 7a, D-37120 Bovenden

+49 (0) 551 / 270766-60

infio@shg-conveyorcontrol.de

address:

SHG Conveyor Control GmbH

Am Teichhof 7a

D-37120 Bovenden

contactinformation:

Tel: +49 (0) 551 / 270766-60

Fax: +49 (0) 551 / 270766-98

info@shg-conveyorcontrol.de

business hours

Mo -Th : 9:00am – 5:00pm

Fr : 09:00an -1:00pm

Sa – So : closed