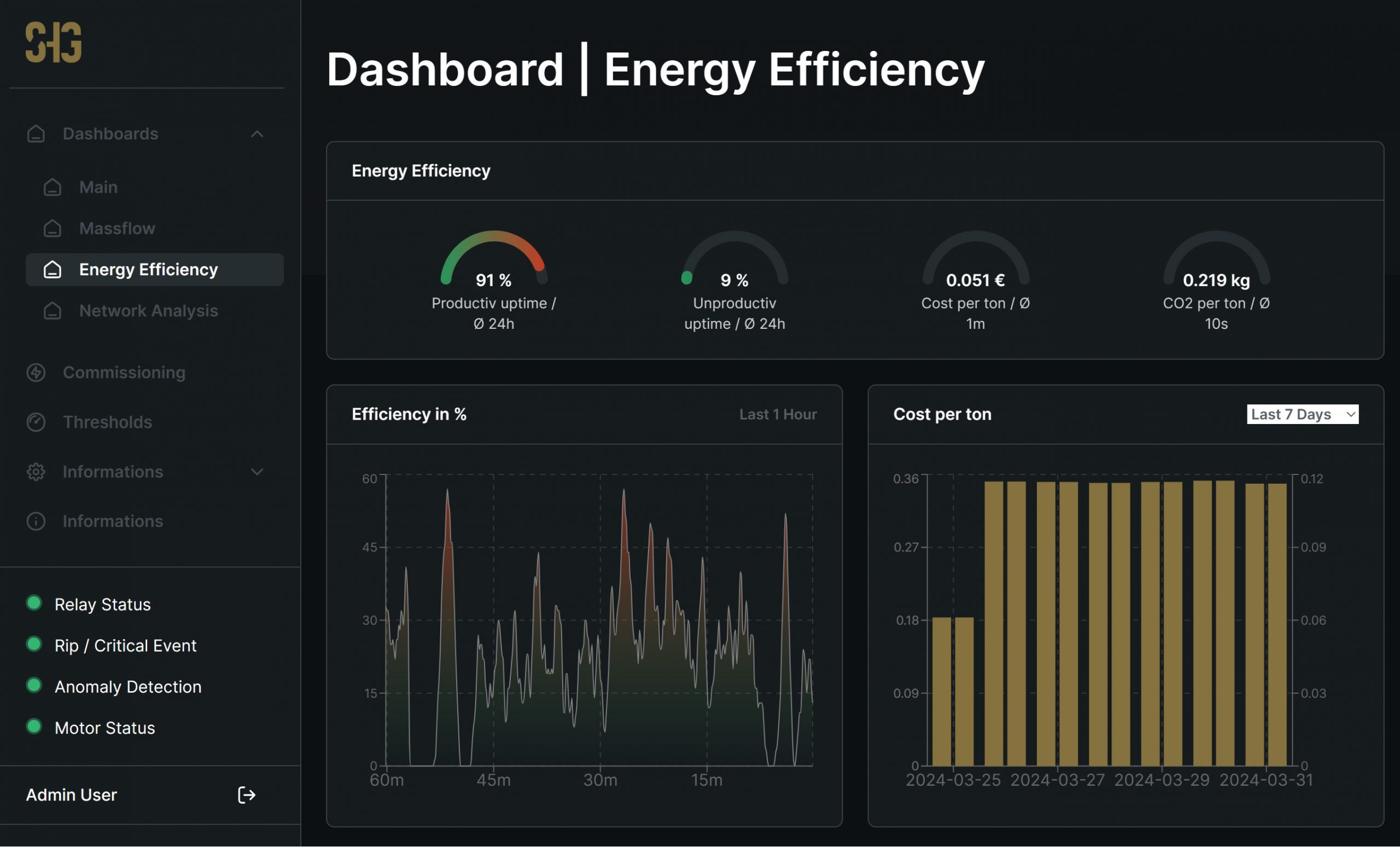

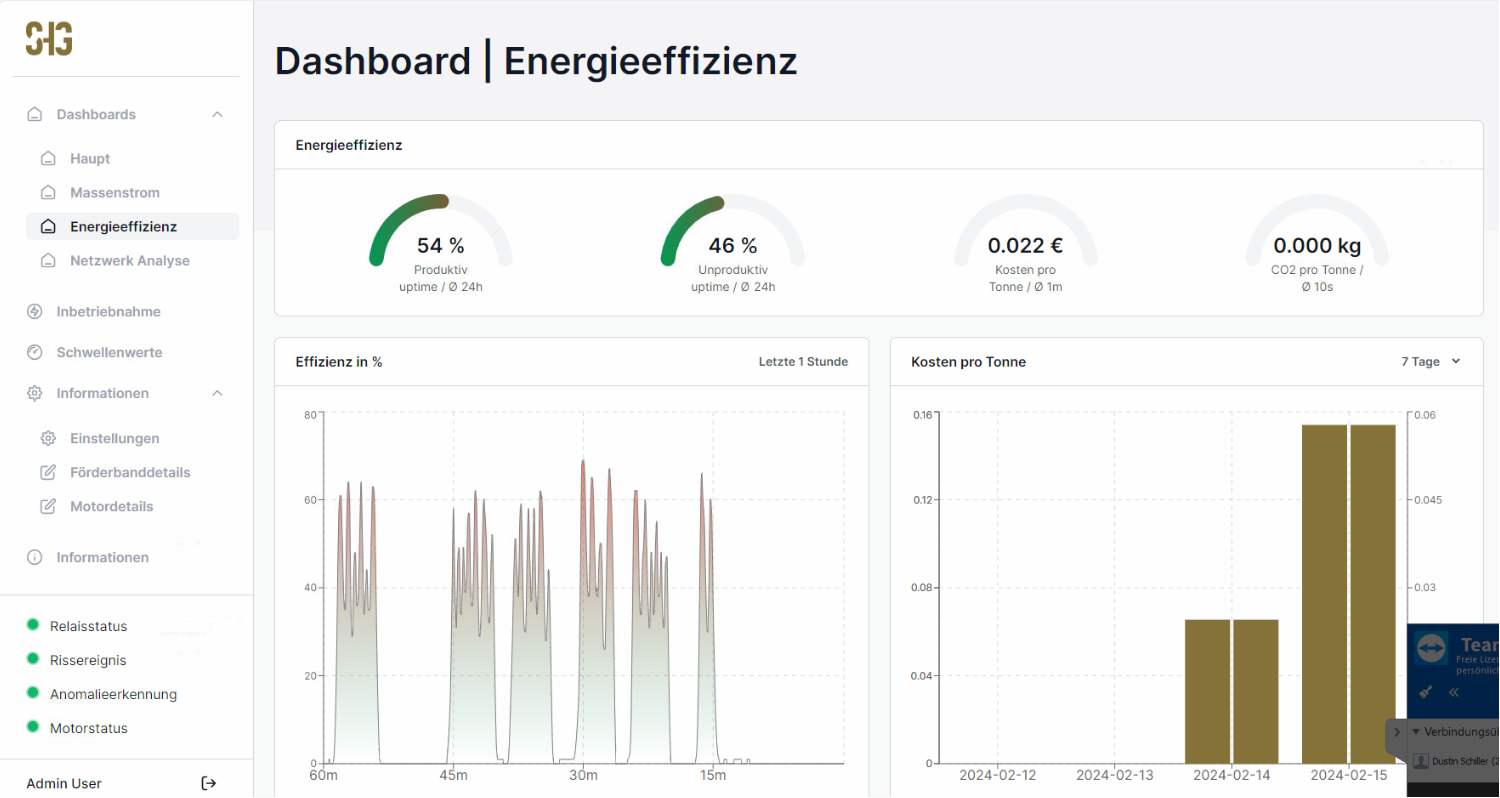

ENERGY EFFICIENCY

Data Analytics – Cost savings – CO2 savings

FUNCTIONAL DESCRIPTION

ENERGIEEFFIZIENZ

Analysing energy efficiency is a matter close to SHG’s heart. Based on the data analysis and the resulting information, SHG makes it possible to increase the energy efficiency of the conveyor system so that the system operator can operate the conveyor system at an optimum energy level. The costs per tonne produced can therefore be reduced to a minimum. This enables CO2 emissions to be reduced and provides a long-term competitive advantage for the customer. Analyses show that systems with a centre distance of 150 m can save around €250 per month, although the effect is significantly greater with long conveyor systems.

INPUT PARAMETERS

- Belt Informations

- Idler Informations

- Belt Speed

- Electrical Parameters

- Massflow

- Temperatur

- …

BENEFITS

- Live calculation of cost per ton

- Utilising the functions of the Rip Prevent+ system

- Process Optimization

- Reduction of CO2 emissions

- Cost savings

- Included in license

- …

RIP PREVENT+ FUNCTION

RIP DETECTION

RIP PREVENTION

ANOMALY DETECTION

MASSFLOW CALCULATION

ELECTRICAL NETWORK ANALYSIS

ENERGYEFFICIENCY

DRIVE MONITORING

FUTURE ADD ONS

IMPRESSIONS

This is how you can reach us!

Am Teichhof 7a, D-37120 Bovenden

+49 (0) 551 / 270766-60

infio@shg-conveyorcontrol.de

address:

SHG Conveyor Control GmbH

Am Teichhof 7a

D-37120 Bovenden

contactinformation:

Tel: +49 (0) 551 / 270766-60

Fax: +49 (0) 551 / 270766-98

info@shg-conveyorcontrol.de

business hours

Mo -Th : 9:00am – 5:00pm

Fr : 09:00an -1:00pm

Sa – So : closed