SCRAPER MONITORING

Fast – Detailed – Cost Effective

FUNCTIONAL DESCRIPTION

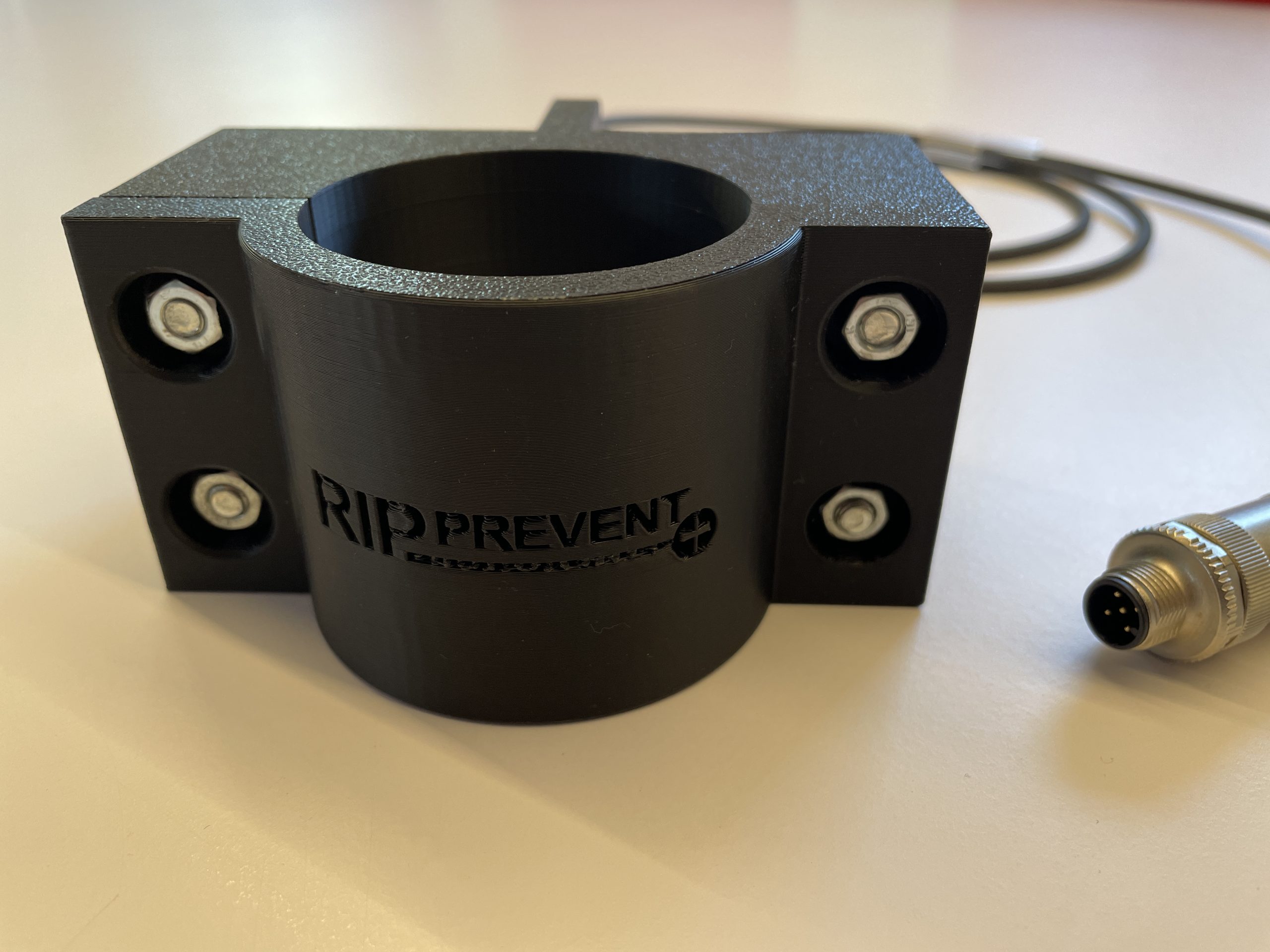

SCRAPER MONITORING

Scraper monitoring is already available on the market, but it is not inexpensive, easy to install and linked to the valuable data of the Rip Prevent+ system, so that a holistic intelligent analysis of the conveyor belt and scraper can be realised. With this additional and valuable data, damage to the surface can be analysed tactically, potential wear of the scraper and whether the scraper is in use. The Rip Prevent+ platform is designed to realise intelligent functions with additional sensors and to view the conveyor system holistically in terms of a Conveyor Health Monitoring System.

INPUT PARAMETERS

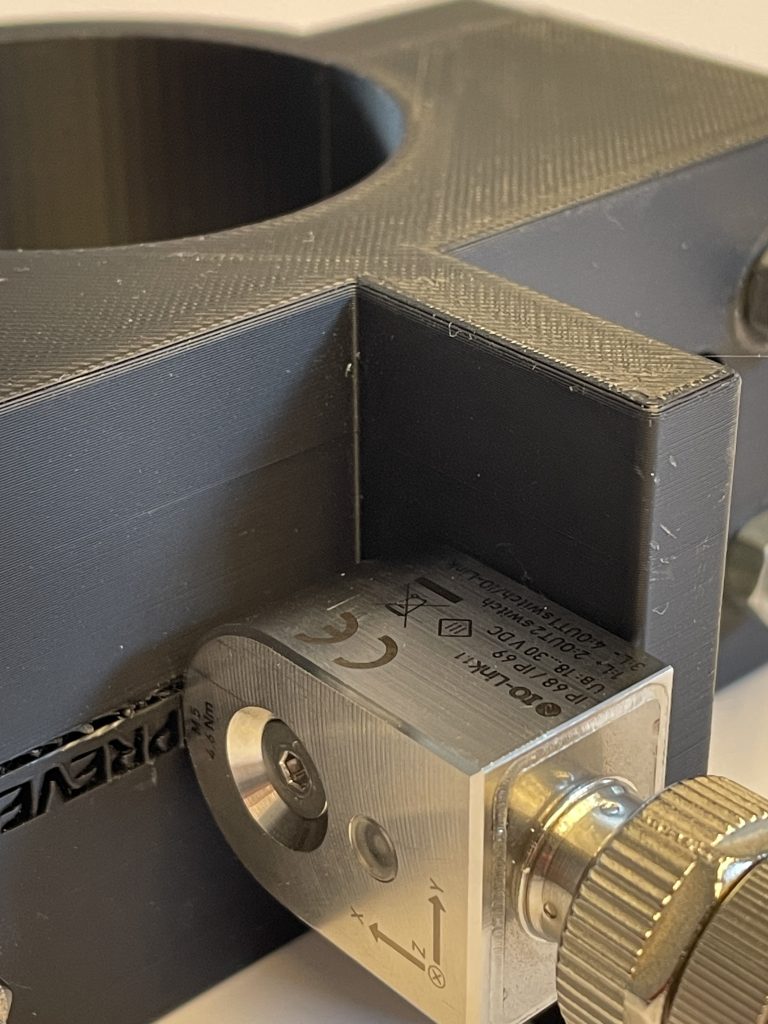

- Vibration Data

- Temperatur

- …

BENEFITS

- Simple retrofitting with Rip Prevent+

- Seamless integration into AI algorithms

- Utilising the functions of the Rip Prevent+ system

- Increased safety

- Reduction of unplanned downtime

- Included in license

- …

RIP PREVENT+ FUNCTION

RIP DETECTION

RIP PREVENTION

ANOMALY DETECTION

MASSFLOW CALCULATION

ELECTRICAL NETWORK ANALYSIS

ENERGYEFFICIENCY

DRIVE MONITORING

GEARBOX MONITORING

BEARING MONITORING

ACCUTRAC

IDLER MONITORING

SCRAPER MONITORING

IMPRESSIONS

This is how you can reach us!

Am Teichhof 7a, D-37120 Bovenden

+49 (0) 551 / 270766-60

infio@shg-conveyorcontrol.de

address:

SHG Conveyor Control GmbH

Am Teichhof 7a

D-37120 Bovenden

contactinformation:

Tel: +49 (0) 551 / 270766-60

Fax: +49 (0) 551 / 270766-98

info@shg-conveyorcontrol.de

business hours

Mo -Th : 9:00am – 5:00pm

Fr : 09:00an -1:00pm

Sa – So : closed