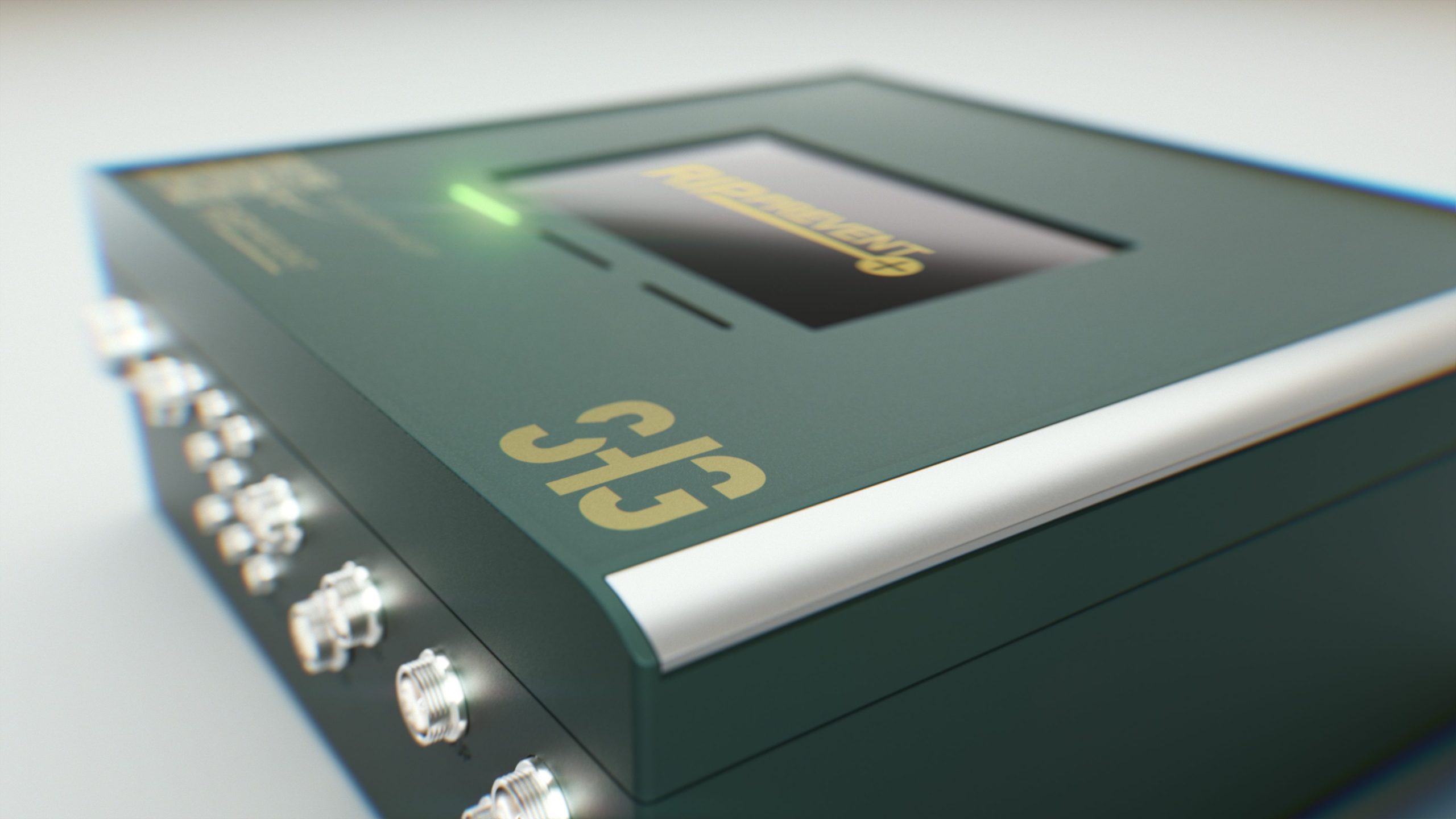

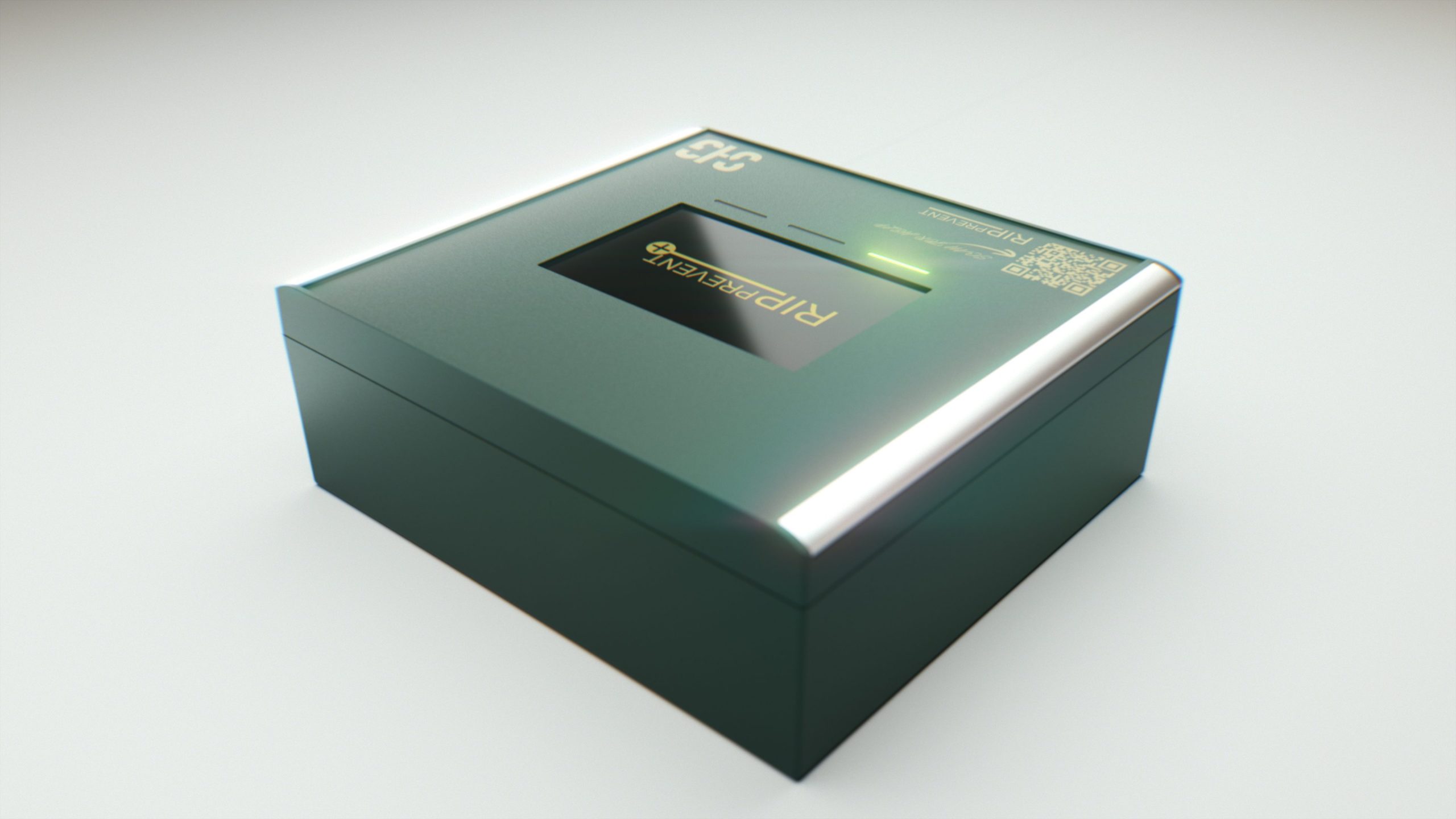

RIP PREVENT+

DiThe simplest, most cost-effective and efficient solution for monitoring and optimising your conveyor belt, your conveyor system and your conveying process

PRODUCT DESCRIPTION

INNOVATIVE CONVEYOR MONITORING SYSTEM

The Belt Monitoring System of the future. The use of artificial intelligence coupled with SHG’s innovative algorithm makes it possible to monitor a critical belt rip, detect anomalies, monitor the motor and increase the efficiency of the conveyor system so that a predictive maintenance approach can be realised without the use of any sensor elements in the conveyor belt or the complex installation of various components to implement the individual functions. The Rip Prevent+ platform offers the option of combining different sensors with each other to get the most out of your data. Rip Prevent means ‘Rest In Peace’ prevention for your conveyor system, so that total failure is minimised.

INPUT PARAMETERS

- Belt Informations

- Idler Informations

- Belt Speed

- Electrical Parameters

- Massflow

- …

APPLICATION FIELD

DaThe SHG Rip Prevent+ system can be used in mining and industrial environments on belt conveyors to detect anomalies, slippage events, grain faults, motor faults, etc. in any conveyor belt. With the SHG Rip Prevent System, special belts such as a corrugated edge belt or a SICON belt can be monitored for the first time.

BENEFITS

- Suitable for all conveyor belts

- No sensor elements inside the conveyor belt required

- No risk of wear

- Suitable for all cover ratios

- Small invest

- Position-independent rip monitoring

- Predictive Maintenance approach

- Lifetime hard and software warranty

- …

TECHNICAL DATA

| Belt Width: | 600 mm – 6000 mm |

| Belt Speed: | bis zu 12 m/s |

| Belt Types: | EP, ST und Spezialgurte |

| Temperature Range: | -20°C bis 55°C |

| Humidity: | 20% bis 90% RH nicht kondensierend |

| System Outputs: |

3x Relais (max. 250V 6A) 1x Ethernet TCP/IP |

| System Inputs: |

88 – 264 VAC 125 – 270 VDC |

| IP Class: |

67 |

| Conformity: | CE, TÜV NRTL, RoHS, (ATEX auf Anfrage) |

| Dimensions: | 300 mm x 330 mm x 120 mm |

RIP DETECTION

RIP PREVENTION

ANOMALY DETECTION

MASSFLOW CALCULATION

ELECTRICAL NETWORK ANALYSIS

ENERGYEFFICIENCY

DRIVE MONITORING

GEARBOX MONITORING

BEARING MONITORING

ACCUTRAC

IDLER MONITORING

SCRAPER MONITORING

IMPRESSIONS

This is how you can reach us!

Am Teichhof 7a, D-37120 Bovenden

+49 (0) 551 / 270766-60

infio@shg-conveyorcontrol.de

address:

SHG Conveyor Control GmbH

Am Teichhof 7a

D-37120 Bovenden

contactinformation:

Tel: +49 (0) 551 / 270766-60

Fax: +49 (0) 551 / 270766-98

info@shg-conveyorcontrol.de

business hours

Mo -Th : 9:00am – 5:00pm

Fr : 09:00an -1:00pm

Sa – So : closed